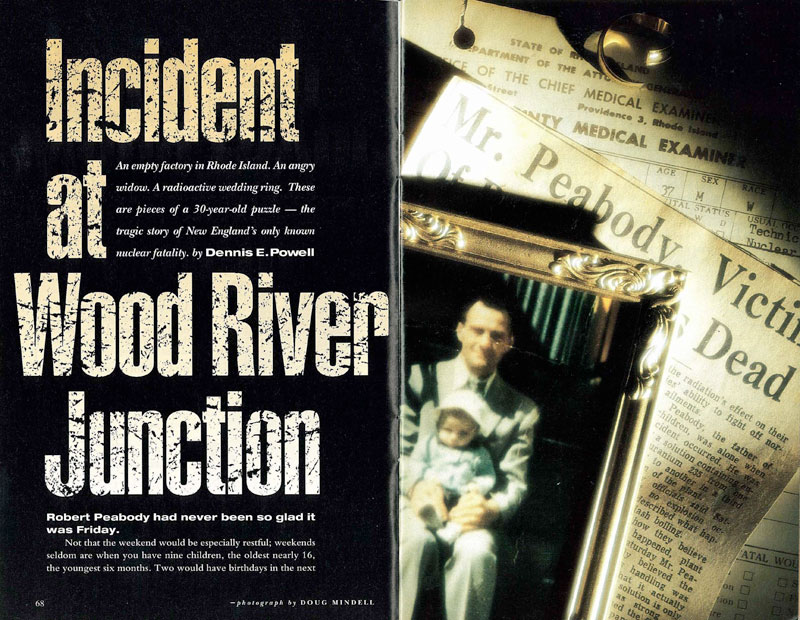

“Incident at Wood River Junction” by Dennis E. Powell | Yankee Magazine, October 1994

Robert Peabody had never been so glad it was Friday.

Not that the weekend would be especially restful; weekends seldom are when you have nine children, the oldest nearly 16, the youngest six months. Two would have birthdays in the next week. Today he had taken some time off to go grocery shopping with Anna, his wife of 17 years. The dozen shopping bags they brought back to their house in Charlestown, Rhode Island, had been full of birthday trimmings.

Or so he mused as he started his car the afternoon of July 24, 1964, for the five-minute drive to the United Nuclear Corporation Fuels Recovery Plant at nearby Wood River Junction. At 37, Peabody was a production operator at the plant. Located in the middle of a 1,200-acre tract nestled in an elbow of the Narragansett Trail, bisected by the main line of the New Haven Railroad and bordering the Pawcatuck River, the plant was a quiet, guarded, slightly mysterious place. United Nuclear had several plants, including ones in downtown New Haven, Connecticut, and White Plains, New York, and rural ones such as the Wood River Junction installation, a similar facility in Hematite, Missouri, and a research lab, complete with reactor, in Pawling, New York.

The plant where Peabody worked used the latest technology. What it was designed to do was simple enough: Take uranium scrap, either spent fuel rods from reactors or the dross from manufacturing, dissolve it in acid, and pass it through a series of processes to recover the enriched uranium it contained. There was no nuclear reactor — all the processes were purely chemical and perfectly straightforward. The place would have been unremarkable save for the fact that it handled uranium, which during even nonnuclear handling is dangerous. Opened only four months earlier, it had not yet actually processed any solid uranium scrap, but was operating on uranium-Iaden liquids called “pickle liquor.”

He had chosen the evening shift so that he would be free during the day for a second job as an auto mechanic. Peabody was a technician, not an engineer or a scientist, meaning that his training consisted of instruction in performing tasks rather than in understanding them. He had spent years in or near the nuclear industry, at the Electric Boat Shipyard in nearby Groton, Connecticut, and with Electric Boat’s nuclear propulsion division in Idaho. And in 1964, he figured, there were two places to be: the space program or the nuclear industry. Of the two, the nuclear industry offered the most promise. It would enable him to make a better life for his family. It would make life better for everyone. One needed only to drive the four hours to the 1964 World’s Fair in New York to see that.

But this week had been a nightmare. On Wednesday, Peabody had been washing equipment on the second floor when a radiation alarm sounded. He and the four others who worked with him on the four-to-midnight shift ran from the building. When none of the several other alarms in the plant went off, and when measuring devices detected no radioactivity, they returned to the building. Water had splashed on the alarm’s electrical contacts, shorting them. Still, it had been quite a scare.

That had been the day, too, when the black goo began appearing near the end of the processing line. It seemed to be some sort of organic compound, but nobody knew quite what it was or where it was coming from. The plant was made up of a series of tanks, long, columnar tubes where materials could be viewed and separated, and evaporating beds, all connected by pipes. When everything was running as it should, the place operated like a factory, with material moving from step to step, growing purer with each new procedure, waste materials drained off at several points along the way. At the end of the line would emerge uranium “rust,” which could be made into nuclear fuel.

The black goo was not part of the plan. By the start of Thursday’s overnight shift, the problem had gotten so bad that some equipment had to be shut down and disassembled for cleaning.

The result was a motley collection of containers, each holding an item or substance that was to some degree radioactive. The covered buckets containing rags and low-level waste were of no particular concern. But there were identical plastic bottles, some filled with highly concentrated uranium solution and some filled with very weak solution. They were labeled as to their contents, but the labels did not adhere well to the bottles, so they were held in place with rubber bands, which themselves were subject to deterioration because of exposure to solvents.

The bottles were of a kind common to the nuclear industry. Called “safe geometry” bottles, they were designed to take advantage of the fact that uranium needs to be physically compact for a nuclear reaction to take place. The shape of these 11-liter bottles, five inches in diameter, and almost four feet long, ensured that even high concentrations would not “go critical” because of the distance between the material at the top of the bottle and the material at the bottom. Of course, the bottles needed to be kept some distance apart, lest the contents of several bottles react, for atomic particles go through plastic as if it were not there at all. Special racks maintained a safe separation.

Were such a highly concentrated uranium solution poured into, say, a large bucket, the uranium atoms would all be closer to each other, producing an uncontrolled atomic reaction called a “nuclear excursion.” The phrase brings to mind happier thoughts, perhaps of the USS Nautilus passing under the polar ice cap or one of the early voyages of the atom-powered Savannah — but several workers at the Los Alamos and Oak Ridge nuclear laboratories had been killed as a result of nuclear excursions.

Consequently, even in 1964 there were tight controls on the handling of radioactive material. Not only did the machines at Wood River Junction have to be carefully drained before disassembly, with the drained liquid and solids accounted for and stored, but even the shop rags needed special treatment. This made even simple repairs long, drawn-out affairs. And this did not appear to be a simple repair.

Workers tended to think of those controls as red tape that hindered their getting at the task at hand. And to make matters worse, nobody was sure what to do about the black goo. While the operating manual dealt with everything that took place during normal operations, it didn’t allow for contingencies such as the appearance of unknown substances in the production line. The workers had to make up procedures as they went along, keeping in mind that the company, or the Atomic Energy Commission, might second-guess them later. Changes in procedure were supposed to be approved by the company’s operations control manager, but he was in Missouri and had not visited Wood River Junction since the plant opened.

By the end of Thursday night’s shift, the system had been repaired and reassembled. But because the production line had been stopped, uranium in various stages of purification had settled in tanks and pipes, as had contaminants that were part of the process, and as had the black goo. The entire line needed to be cleaned, adding to the collection of containers. By Friday afternoon there was some confusion as to which bottles held what concentrations of uranium. One bottle, containing highly concentrated material, appeared to be leaking onto the floor. And the II-liter bottles had never before been used to store such concentrated uranium in the production area.

Peabody arrived for his Friday night shift, early as usual, said hello to the security guard, Howard Coon, 43, and walked into the changing room, where he put on his working clothes. He joked with George Spencer, 33, and Robert Mastriani, 27, who, like Peabody, were plant technicians. They talked about the upcoming weekend and about the events of the last couple of days, shook their heads at all the work ahead of them. Then they reported to their supervisor, Clifford Smith, a 30-year-old chemist, who had been meeting with the facility’s superintendent, Richard Holthaus. Though the fuels recovery plant was a fairly big and highly technical operation, each shift comprised only five people: three technicians, a supervisor, and a security guard, though the superintendent was on hand during the day and at other times when the situation warranted.

Smith outlined the evening’s tasks: the usual shutdown procedures, plus sorting out and putting in their proper place all the materials left over from the week’s problem with the black goo. The men went to work.

Part of the uranium refinement procedure was to “wash” the uranium with trichloroethane – common dry-cleaning fluid. This dissolved any oils or kerosene that had contaminated the uranium scrap. But it also picked up a small amount of uranium, turning the normally clear cleaning liquid bright yellow and requiring that the solvent itself be washed. So each week the used cleaning liquid was drained into the 11-liter “safe” bottles, the same sort of bottles that now contained concentrated uranium solution. A sodium carbonate solution was added, and the bottle, weighing 35 pounds or more, was shaken vigorously. In due course the oils would float to the top, the uranium would combine with the sodium carbonate and settle to the bottom, and clear, clean trichloroethane would remain in the middle. The whole thing looked like a giant bottle of Italian salad dressing. The oil would be disposed of, typically in the incinerator; the solvent would be poured off for reuse; and the uranium compound would go back into the system for further refinement.

Shaking a 35-pound bottle for 20 minutes was no one’s idea of a good time. And there was a lot of solvent to be cleaned. But a week earlier one of the operators had had an idea: On the third floor there was a vat with a mixer attached, a stainless-steel contraption that looked like a huge malted-milk machine. Why not pour the contaminated trichloroethane into it and let the mixer do the work? The supervisor on duty at the time considered the plan and decided that as long as the material was not highly radioactive, the procedure would be safe. So they tried it on that shift, and it worked. The supervisor of another shift, hearing about it, went through the roof. It was unsafe, he said. But he was talked out of his objections.

At about 6:00 P.M. Friday, Robert Peabody went to wash the week’s trichloroethane in the mixing vat upstairs. He grabbed an 11-liter bottle filled with bright yellow liquid and carried it up the stairs to the third floor. The tag that identified the contents must have slipped out of its rubber bands — it was later found on the floor in the stairway.

The bottle did not contain trichloroethane. It contained a very high concentration of enriched uranium, drained from the system during the black goo crisis.

When Peabody reached the room with the mixer, he poured sodium carbonate solution into the vat and turned on the mixer. Then he lifted the 11-liter bottle. It was a strain, because the edge of the vat was five feet above the floor, but Peabody, though only 5’6″, was a strong man. He cradled the bottle in his left arm, using his arm as the fulcrum, and raised the bottle’s bottom with his right hand, pouring the contents into the vat. The bottle was not quite empty when something went terribly wrong.

“Oh, my God!” shouted Peabody, but his words were drowned out by the shriek of sirens going off throughout the building. Not just one alarm this time. All of them. A flash of blue light emanated from the mixing vat, which now erupted in hot, glowing liquid that splashed as high as the 12-foot ceiling. Peabody was knocked backward. He knew instantly what had happened: Somehow, the mixture in the vat had achieved criticality. Instead of a mixing machine processing solvent, he had an uncontrolled nuclear reactor.

He let go of the bottle, which slid upside down into the mixer. He ran from the room.

He was already a dead man, and he knew it.

What had happened was this: The uranium mixture had been in its safe geometry bottle, so although there was enough of the fissionable material to create a nuclear reaction, it was spread out over sufficient distance to keep a reaction from taking place. But when it was poured into the vat, 18 inches in diameter, it was physically concentrated. A reaction began instantly. Peabody was bombarded with an enormous number of neutrons as well as gamma rays.

He dashed down the stairs, yanked open the door at the bottom of the three-story tower, and ran toward the facility’s emergency shack, 450 feet away, tearing off his clothing as he ran. He had been splashed with the uranium mixture, and if there was even a slight chance of his survival, it required limiting his further exposure. The others, all of whom had been working on the first floor, were running there, too; this did not sound like another false alarm. If there was any doubt in their minds, it was dispelled by the sight of Peabody, naked and shouting, running for the shack. He fell to the ground before reaching the shack, and lay there, vomiting and beginning to bleed from his nose and ears. The others bundled him in a blanket kept in the shack. He remained on the ground, though twice he got up and walked around briefly. He felt terribly ill, sometimes confused. His belly was wracked with cramps. He spoke very little.

Clifford Smith, the plant supervisor, quickly phoned the Hope Valley Ambulance Corps. The ambulance arrived at about 7:00 P.M., loaded up the injured man, and drove to Westerly Hospital. But Westerly lacked facilities to treat radiation injuries, so they diverted to Rhode Island Hospital in Providence, arriving about 7:45. George Spencer sat in the back of the ambulance with Peabody.

Company officials and the state police rushed to the plant. A state policeman was dispatched to find Anna Peabody and take her and her oldest son, Charles, to the hospital. All the officer told them was that there “had been an accident.”

Back at the plant, it wasn’t clear whether the nuclear reaction was still taking place. Someone would have to go inside and find out. At about 7:15 P.M., the superintendent, Richard Holthaus, entered the building. He carried radiation measuring equipment and was able to determine that the first floor was relatively safe. He went back in a few minutes later with supervisor Smith. At about 7:45, the pair went into the building for a third time, determined to do whatever was necessary to end any reaction that continued.

As they reached the third-floor room containing the mixer, they saw the bottle resting in the still-operating mixer, the yellow liquid splattered over the walls, ceiling, and floor. Radiation detectors suggested that the room could be entered briefly. Holthaus strode in quickly and flipped off the mixer, then rushed out of the room.

Good thing. The reaction had stopped because about 20 percent of the liquid had splashed out of the tank, and the mixer had spun the remainder around the sides of the vat, spreading it sufficiently to make it subcritical. But when the mixer was switched off, the liquid settled, and a second, less violent nuclear reaction took place. Fortunately, the settling took long enough that Holthaus was out of the room and shielded by a foot-thick concrete block wall by the time it commenced. It lasted only a few seconds; the liquid quickly boiled, and the bubbles created were enough to end the criticality.

During the next half hour Smith and Holthaus drained the vat into small bottles, eliminating the chance of further “nuclear excursions.” Later investigations would determine that they had received high, though not immediately life-threatening, doses of radiation. The silver coins they carried in their pockets were now radioactive.

As was the wedding ring of Robert Peabody. As was, in fact, Robert Peabody himself.

When Anna and Chickie, as their son Charles was called, arrived at the hospital, they were allowed to enter the specially isolated emergency room that had been hastily prepared for Peabody. After they had been with him for a few minutes, they were cautioned by a physician to stay near the foot of the bed, rather than stand near his upper body.

Peabody was conscious and lucid. He was also restless, so he was given a sedative. “Somebody put a bottle of uranium where it wasn’t supposed to be,” he told his anguished wife and son. This point would later be disputed by the company, but federal authorities were never able to firmly establish who was at fault. And the testimony of Peabody would not be available.

In the hours following his admission to the hospital, he seemed to recover a little from the shock. But by Sunday morning it was evident that his body was shutting down, dying at the cellular level. There were none of the secondary symptoms often associated with radiation exposure — loss of hair, blindness — because they did not have time to kick in. He had been bombarded with neutrons, just as if he’d been near a neutron bomb, the devices that kill people but leave buildings intact.

There was no real treatment at the time for radiation exposure; indeed, there is none today. The best doctors could do was treat the irradiated man’s symptoms. He continued to vomit and experience cramps. His left hand, which had been directly exposed to the reaction, began to swell. It was necessary to saw off his wedding ring, over his objections. His blood pressure dropped. Sunday afternoon, he slipped into a coma. He died on Sunday night, 49 hours after the accident. His family had not been allowed to see him since early Saturday.

Calculations based on analysis of his gold wedding ring and on tissue samples showed that he had received more than 700 rems of radiation, the equivalent of 700,000 chest Xrays; anything above 350 rems is always fatal. Robert Peabody had been exposed to more radiation than anyone outside of Hiroshima or Nagasaki.

Weeks later, Anna Peabody was given what she was told were her husband’s ashes. She did not then and does not now believe they were his ashes. They were not even slightly radioactive. The family believes that his body is stored away in some laboratory somewhere, and though they understand how this might have been necessary, they are angry at what they believe to be an attempt to mislead them.

They remain angry, 30 years later, over what they see as shabby treatment. A month after the accident, Anna Peabody received her husband’s last paycheck from United Nuclear Corporation. It was accompanied by a letter full of legalisms, but not a word of sympathy. It was almost as if he had been fired. The family received sympathetic telegrams from Governor John Chafee and President Lyndon Johnson. Later, a puzzling certificate arrived, signed by the president, praising Peabody for having died in his country’s military service. Robert Peabody had not been in the service for 20 years.

A lawsuit was brought and settled; Anna Peabody’s portion of the settlement was $22,000 — a considerable sum in 1964, when a new Oldsmobile cost less than $3,500, but very little with which to raise nine children. The family got by on Peabody’s Social Security survivors’ benefits, and Anna is proud of the fact that all nine children graduated from high school. She remains bitter over the incident, though, in no small measure because of the throat cancer she suffered in 1985. She believes that it may have resulted from the time she spent with her dying, radioactive husband, whom she continues to mourn.

Detailed follow-up records of the other Wood River Junction workers who had been exposed to significant radiation were not kept; they were not required at the time. The Atomic Energy Commission eventually charged United Nuclear Corporation with 14 violations of nuclear safety regulations, eight directly involved in the accident; but no fines were ever levied.

Though the story received considerable attention at the time, it was quickly forgotten. In1964 Robert Peabody’s death was seen as an industrial accident — a particularly horrible one, but nothing to trigger any wider alarm. Neighbors of the Wood River Junction plant told reporters they had no plans to move away and expressed continued faith in the bright promise of nuclear energy. After decontamination, the plant reopened in February 1965 and went back to reprocessing uranium.

Over the next few years a number of other United Nuclear Corporation plants would close, the one in Pawling, New York, following an explosion involving deadly plutonium. Eventually, the company divested itself of all its nuclear businesses and changed its name to UNC. There are currently no nuclear fuels reprocessing plants in New England. Wood River Junction closed in 1980 — one year after the accident at the Three Mile Island nuclear plant in Pennsylvania galvanized public opposition to nuclear power.

The site has been considered for a number of development projects, but UNC cannot sell the land until the Nuclear Regulatory Commission (the federal agency that succeeded the Atomic Energy Commission) grants its request for a “termination of license,” which certifies that the site is free from contamination and safe to use. The plant is now a guarded shell, eerie as a tomb, its robin’s-egg-blue paint peeling off in sheets the size of dinner plates.

Ironically, the incident at Wood River Junction may say more about the safety record of the nuclear industry than about its failings. The physicians who attended the agonizing death of Robert Peabody published a paper about his case in The New England Journal of Medicine in April 1965. It began with this confident assertion: “The acute radiation syndrome will almost surely be encountered from time to time as accidents occur in the rapidly expanding nuclear industry.”

As it turned out, they were wrong on both counts. Since the late seventies, the growth of the nuclear industry has come to a virtual halt, due to declining oil prices, exploding construction costs, and concerns about safety. And according to the Nuclear Regulatory Commission, Robert Peabody was the U.S. nuclear industry’s first and last fatality due to acute radiation syndrome.

Excerpt from “Incident at Wood River Junction,” Yankee Magazine, October 1994

The post Nuclear Fatality at Wood River Junction | Yankee Classic appeared first on New England Today.